Paper Converting Knives

Starting from paper conversion blades,KNT Knives partners with both world-famous paper machinery makers and paper mills.Whatever your conversions process,from slitting and rewinding to sheeting,and whatever your material including tissue paper,standard paper and cardboard,we offer blades to get the job done right.

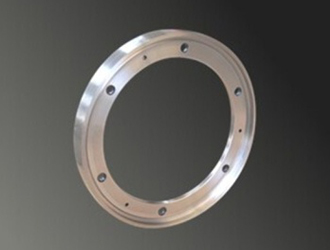

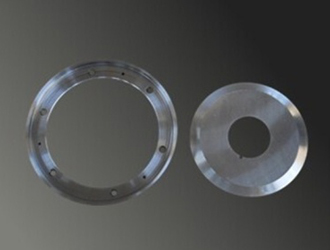

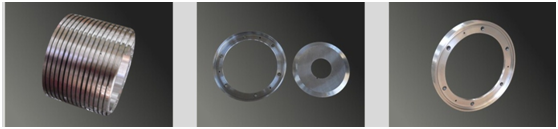

◆Rewinding Slitting Blades

As an important facility in the paper-making industry,a slitter rewinder is to make the paper rolls into wanted width through slitting and trimming processes

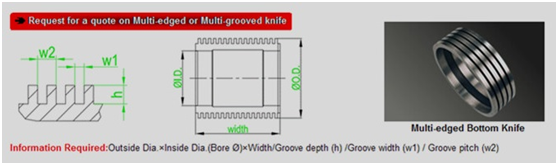

Rewinding slitting blade consists of top slitter blade and bottom slitter blade. The top slitter blade can be dish shaped or flat shaped with single, double bevel edged or square edged. For the score cutting, there are only one blade works as the roll or sleeve stand as the bottom blade.

TCT bottom knife has become one of our speciality items that we focus on.Both single tipped or dual tipped knives are available.Featuring reliability,no fall-off,wear-resistance and long life,our knife is 100% a good substitute for imported knives.

Specifications of Rewinding Slitting Blades

|

Top Rewinder Slitter blades |

|||

|

Specification(mm) |

OD |

ID |

Thickness |

|

φ100*φ60*4 |

100 |

60 |

4 |

|

φ150*φ90*2/3 |

150 |

90 |

2/3 |

|

φ190*φ75*2/3 |

190 |

75 |

2/3 |

|

Bottom Rewinder Slitter blades |

|||

|

Specification(mm) |

OD |

ID |

Thickness |

|

φ230*φ115*20 |

230 |

115 |

20 |

|

φ250*φ140*20 |

250 |

140 |

20 |

|

φ250*φ140*25 |

250 |

140 |

25 |

|

φ250*φ188*15 |

250 |

188 |

15 |

|

φ250*φ188*25 |

250 |

188 |

25 |

|

φ305*φ230*37 |

305 |

230 |

37 |

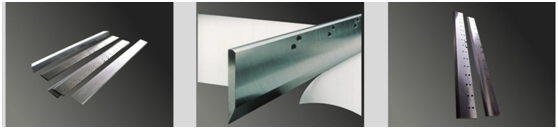

◆Guillotine blades

By quitting the traditonal inlaying method in a coke furnace,the new inlaying process improves with a tail gas furnace.Electric heating brings equal and accurate temperature degrees,and gas protection helps achieve no oxidized welding,therefore tipped area welded onto base metal without such defects as imcomplete or unthorough welding.Morever,welding and heat treatment are done in the same heating & cooling system,knives therefore brightly quenched with an equal hardness up to HRc63-65.

Deep cryogenic treatment at liquid-nitrogen temperatures (-196°C) further improves the knife a lot on steel hardness and red hardness,wear and impact resistance ability,thus giving a liftime 2-3 times longer than a knife normally treated.

Specifications of Guillotine blades

|

Brand |

Specification (mm) |

Length |

Width |

Thickness |

|

Polar 78/80 JUNIOR |

960 x 107 x 9.7 |

960 |

107 |

9.7 |

|

Polar 86 |

1080 x 115 x 11.7 |

1080 |

115 |

11.7 |

|

Polar 90/92 |

1095 x 115 x 11.7 |

1095 |

115 |

12.7 |

|

Polar 115 |

1390 x 160 x 13.75 |

1390 |

160 |

13.75 |

|

Polar 137 |

1605 x 160 x 13.75 |

1605 |

160 |

13.75 |

|

Schneider Senator 92 MC |

1090 x 132 x 10 |

1090 |

132 |

10 |

|

Schneider Senator 115 MC |

1350 x 144 x 10 |

1350 |

144 |

10 |

|

Perfecta 92 |

1090 x 140 x 12 |

1090 |

140 |

12 |

|

Perfecta 115 |

1350 x 140 x 12 |

1350 |

140 |

12 |